A gas furnace baseboard heating system is a popular choice for homeowners seeking an efficient and reliable heating solution, particularly in colder climates. This system combines the energy-efficient performance of a gas furnace with the targeted heating capabilities of baseboard units, providing a comfortable and cost-effective heating experience.

What are the Advantages of a Gas Furnace Baseboard Heating System?

1. Energy Efficiency

While baseboard heating systems are generally less efficient than forced-air systems, a gas furnace baseboard heating system can offer better efficiency compared to electric baseboard heaters. This is because gas furnaces can achieve higher efficiency ratings, often above 80%, which can lead to cost savings on fuel.

2. Cost Savings

Using a gas furnace can be more cost-effective than electric baseboard heaters, especially in areas where natural gas is cheaper than electricity. This can result in significant savings on energy bills over time.

3. Comfort Levels

Gas furnace baseboard heating systems can provide consistent and reliable heat, especially in colder climates. They warm objects and people directly, which can make the space feel warmer even at lower thermostat settings, resulting in a more comfortable living environment.

4. Zone Heating

Each baseboard unit can have its own thermostat, allowing for zone heating where you can control the temperature in individual rooms. This can further optimize energy use by heating only the rooms that need it, rather than heating the entire home uniformly.

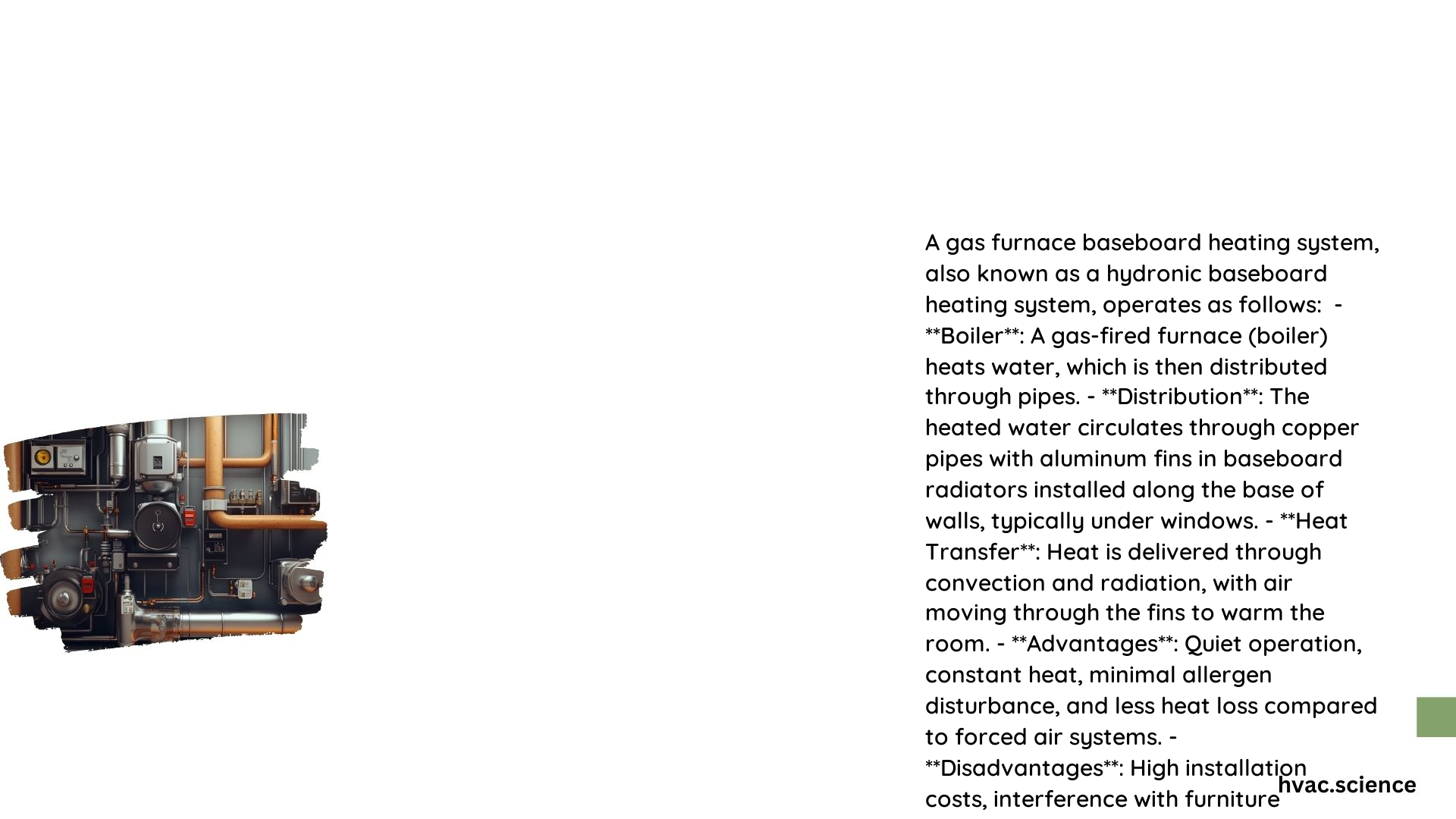

How Does a Gas Furnace Baseboard Heating System Work?

1. Gas Combustion

The process begins with the combustion of natural gas in the furnace. This combustion heats a heat exchanger, which then warms water or a fluid.

2. Heat Exchange

The heated water or fluid is distributed through a network of pipes to the baseboard heaters located in various rooms.

3. Distribution of Warm Air

At the baseboard heaters, the warm fluid heats metal fins, which then transfer the heat to the room through convection. Cold air is drawn into the baseboard heater, warmed, and then rises into the room, providing a comfortable and even heat distribution.

What are the Key Components of a Gas Furnace Baseboard Heating System?

1. Gas Furnace

The gas furnace is the central unit where gas combustion occurs to heat the water or fluid. It is typically located in a basement or utility room.

– Function: To heat the fluid or water that will be distributed to the baseboard heaters.

– Specifications: Efficiency ratings, fuel type (natural gas), and capacity (BTUs).

2. Baseboard Heaters

These are the units installed in each room to distribute the heat.

– Function: To transfer heat from the fluid to the room through convection.

– Specifications: Type (hydronic), material (metal fins), and thermostat control.

3. Thermostats

Each baseboard heater can have its own thermostat to control the temperature in individual rooms.

– Function: To regulate the temperature by controlling the flow of heated fluid to the baseboard heaters.

– Specifications: Digital or analog, programmable, and zone control capabilities.

4. Piping

This includes the network of pipes that distribute the heated fluid from the furnace to the baseboard heaters.

– Function: To transport the heated fluid efficiently with minimal heat loss.

– Specifications: Material (copper, PEX), insulation, and sizing.

What are the Maintenance and Repair Costs for a Gas Furnace Baseboard Heating System?

Routine Maintenance

Annual maintenance tasks include cleaning the furnace, inspecting and cleaning the baseboard heaters, and checking the piping for leaks. Average cost: $100-$300 per year, including labor.

Common Repairs

Common repairs include replacing worn-out parts like thermostats, valves, and pumps. Average cost: $200-$500 per repair, including labor.

Potential Replacement Parts

Parts that may need replacement over time include the furnace heat exchanger, baseboard heater elements, and piping components. Average cost: $500-$2,000 per part, including labor.

Frequency of Service

It is recommended to have the system serviced annually to ensure optimal performance and efficiency.

By understanding the advantages, operational mechanics, key components, and maintenance requirements of a gas furnace baseboard heating system, homeowners can make an informed decision about whether this heating solution is the right fit for their home and budget.